|

|

Terminology Explanation |

|

| 3/4 Extension |

| slide extends approximately 3/4 of the total slide length, for applications not requiring complete access to drawer/components. |

|

| Over Extension

|

| slide extends further than the length of the slide allowing total and easy access to the drawer/components, often a convenient feature. |

|

| Full Extension

|

| slide extends the same amount as the slide length allowing full access to drawer/components. |

|

| Lever Disconnect

|

| Actuate the latch and the drawer can be removed from the main unit. |

|

| Lock-out

|

| Holds the slide open or closed until extra force is applied to overcome the detent |

|

| Stopper (Detent)

|

| Holds the slide open or closed until extra force is applied to overcome the detent |

|

| Self-Closing Latch

|

| Automatic closing spring system. Drawer will close by itself. |

|

|

|

|

|

Features |

|

| Smooth Action |

| The exceptional accuracy that comes from precision roll forming machines that all bearings come in contact, improving the stability and life of the product. |

|

| High tolerance |

High precision slide rail with minimum deflection by

-

Build and maintain own tools including progressive dies and roll forms

-

Rapid time-to-market soft tooling solutions

-

Standardized tooling methods worldwide |

|

| Corrosion resistance |

| Test by 5% Salt Spraying for 96 hours |

|

|

|

|

|

|

|

Spec |

|

| Slide members & ball retainers : Use only center-cut Cold rolled steel for high consistency

Ball bearings : High carbon steel (Grade 100)

Finish : Standard bright electro zinc plate

Lubricant : Hi-Lo temperature grease

Temperature range : -40F(4C) to +130F(+55C) |

|

|

|

Slide Member Clamping Screw |

|

| Side mounting with holes for #8 pan head screws. Use #4(M3) or #8(M4). |

|

|

|

|

|

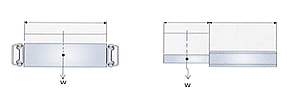

Slide Member Fixation Method |

|

| Use Inner Member access Hole for Outer Member mounting |

|

|

|

|

|

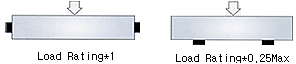

Load Rating |

|

| Load rating can be differ from slide length and travel length. |

|

|

|

|

|

Life Cycle

|

|

Life Cycle |

Load Rating |

10,000 X |

load rating X 1 |

50,000 X |

load rating X 0.8 |

100,000 X |

load rating X 0.7 |

500,000 X |

load rating X 0.5 |

1,000,000 X |

load rating X 0.2 |

|

|

|

|